info@gerb.com

Floating Slab Track with GERB Spring Elements for Thomson-East Coast Line

One of the world‘s longest driverless rapid transit lines with GERB spring elements in Singapore

From Woodlands north to Sungei Bedok, Thomson-East Coast

Line (TEL) will serve 32 stations in over 43 kilometers lenght. When

completed in 2022, TEL will be one of the longest driverless rapid

transit lines in the world. Construction program already started in

2014 and was carried out by Land Transport Authority Singapore

and China Railways First Group. When fully opened, it is expected to

serve about 500,000 commuters daily in the initial years, rising to one million commuters daily in the long term.

A GERB Floating Slab Track system was installed to enable the

Mass Rapid Transit a smooth operation without interference of

structure-borne noise and vibration.

Challenge

The challenge within this project was to reduce the transmission of noise and vibration most effectively to the surrounding. Vibrations from passing trains are also transmitted to buildings in the nearby area and radiated as secondary airborne noise and vibration. The sensitive section is located in a tunnel and the total length of the tracks that need to be isolated was about 2 km.

Further technical requirements for the FST System were:

- the achieved natural frequency no greater than 6.5 Hz

- the insertion loss of the FST system was required to be not less than 20 dB

- The design life of the springs to be at least 40 years

- Very high quality control requirements

Technical Facts:

Vibration Source: Train Traffic in the underground system of MRT

Base Isolation Frequency: 5.7 Hz Floating Slab Track

Design Load: 160 kN

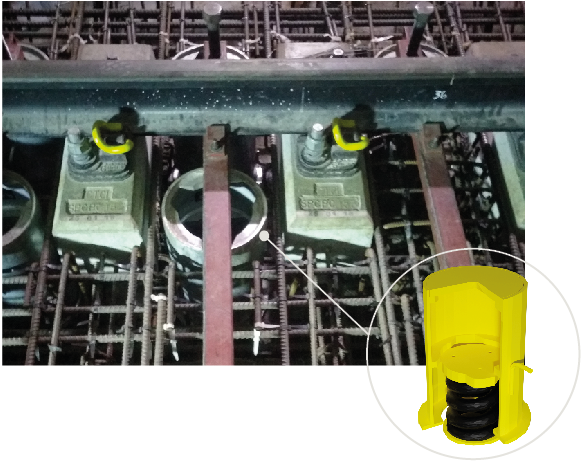

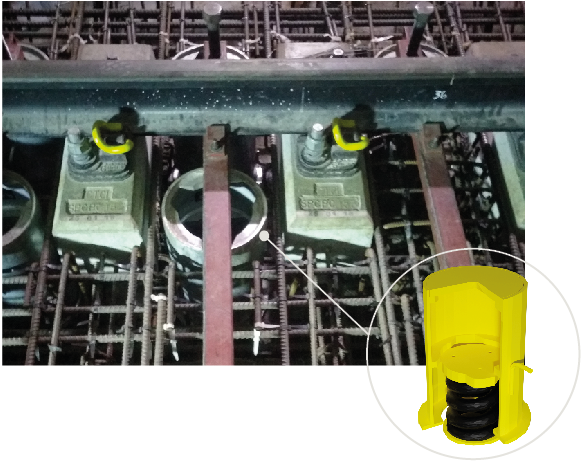

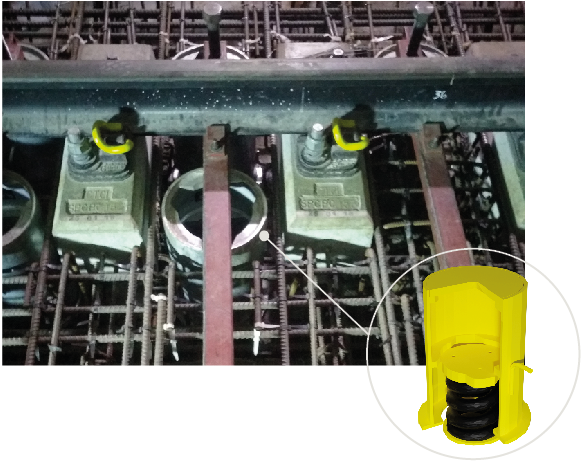

GERB Elements: GSI steel spring R81

Solution

GERB‘s solution for TEL started with engineering services that were necessary for the completion and installation of the FST System. This included determinating and evaluating natural frequencies as well as the deflection of slabs and springs caused by vertical and horizontal static and dynamic loads.

The calculations were performed using a finite-element computer

program. The 3D calculation model consists of a spring-supported

plate system taking the rails fixed on baseplates into consideration

as well as the shear links (dowels) arranged between the slabs.

Our proposed FST System was accepted by the client and

production phase began. GERB experts accompanied the

construction process from day one.

Result

As originally planned and specified through the tender documentation, the design of the FST trackwork provided a safe, durable, comfortable,

and reliable design in addition to fulfilling all of the requirements for insulation, corrugation mitigation, ground-borne noise and vibration attenuation, corrosion protection and electromagnetic compatibility.

Further Resources

You need further information on this topic?

Please do not hesitate to contact us with your individual question.

One of our project engineers will get back to you shortly.

Floating Slab Track with GERB Spring Elements for Thomson-East Coast Line

One of the world‘s longest driverless rapid transit lines with GERB spring elements in Singapore

From Woodlands north to Sungei Bedok, Thomson-East Coast Line (TEL) will serve 32 stations in over 43 kilometers lenght. When completed in 2022, TEL will be one of the longest driverless rapid

transit lines in the world. Construction program already started in 2014 and was carried out by Land Transport Authority Singapore and China Railways First Group. When fully opened, it is expected to serve about 500,000 commuters daily in the initial years, rising to one million commuters daily in the long term.

A GERB Floating Slab Track system was installed to enable the

Mass Rapid Transit a smooth operation without interference of

structure-borne noise and vibration.

Floating Slab Track with GERB Spring Elements for Thomson-East Coast Line

One of the world‘s longest driverless rapid transit lines with GERB spring elements in Singapore

From Woodlands north to Sungei Bedok, Thomson-East Coast Line (TEL) will serve 32 stations in over 43 kilometers lenght. When completed in 2022, TEL will be one of the longest driverless rapid transit lines in the world. Construction program already started in 2014 and was carried out by Land Transport Authority Singapore and China Railways First Group. When fully opened, it is expected to serve about 500,000 commuters daily in the initial years, rising to one million commuters daily in the long term.

A GERB Floating Slab Track system was installed to enable the Mass Rapid Transit a smooth operation without interference of structure-borne noise and vibration.

Challenge

The challenge within this project was to reduce the transmission of noise and vibration most effectively to the surrounding. Vibrations from passing trains are also transmitted to

buildings in the nearby area and radiated as secondary airborne noise and vibration. The sensitive section is located in a tunnel and the total length of the tracks that need to be

isolated was about 2 km.

Further technical requirements for the FST System were:

- the achieved natural frequency no greater than 6.5 Hz

- the insertion loss of the FST system was required to be not less than 20 dB

- The design life of the springs to be at least 40 years

- Very high quality control requirements

Technical Facts:

Vibration Source: Train Traffic in the underground system of MRT

Base Isolation Frequency: 5.7 Hz Floating Slab Track

Design Load: 160 kN

GERB Elements: GSI steel spring R81

Challenge

The challenge within this project was to reduce the transmission of noise and vibration most effectively to the surrounding. Vibrations from passing trains are also transmitted to buildings in the nearby area and radiated as secondary airborne noise and vibration. The sensitive section is located in a tunnel and the total length of the tracks that need to be

isolated was about 2 km.

Further technical requirements for the FST System were:

- the achieved natural frequency no greater than 6.5 Hz

- the insertion loss of the FST system was required to be not less than 20 dB

- The design life of the springs to be at least 40 years

- Very high quality control requirements

Further Technical Facts:

Vibration Source: Train Traffic in the underground system of MRT

Base Isolation Frequency: 5.7 Hz Floating Slab Track

Design Load: 160 kN

GERB Elements: GSI steel spring R81

Solution

GERB‘s solution for TEL started with engineering services that were necessary for the completion and installation of the FST System. This included determinating and evaluating natural frequencies as well as the deflection of slabs and springs caused by vertical and horizontal static and dynamic loads.

The calculations were performed using a finite-element computer program. The 3D calculation model consists of a spring-supported plate system taking the rails fixed on baseplates into consideration as well as the shear links (dowels) arranged between the slabs. Our proposed FST System was accepted by the client and production phase began. GERB experts accompanied the construction process from day one.

Solution

GERB‘s solution for TEL started with engineering services that were necessary for the completion and installation of the FST System. This included determinating and evaluating natural frequencies as well as the deflection of slabs and springs caused by vertical and horizontal static and dynamic loads.

The calculations were performed using a finite-element computer

program. The 3D calculation model consists of a spring-supported

plate system taking the rails fixed on baseplates into consideration

as well as the shear links (dowels) arranged between the slabs.

Our proposed FST System was accepted by the client and

production phase began. GERB experts accompanied the

construction process from day one.

Result

As originally planned and specified through the tender documentation, the design of the FST trackwork provided a safe, durable, comfortable, and reliable design in addition to fulfilling all of the requirements for insulation, corrugation mitigation, ground-borne noise and vibration attenuation, corrosion protection and electromagnetic compatibility.

Result

As originally planned and specified through the tender documentation,

the design of the FST trackwork provided a safe, durable, comfortable,

and reliable design in addition to fulfilling all of the requirements for

insulation, corrugation mitigation, ground-borne noise and vibration

attenuation, corrosion protection and electromagnetic compatibility.

Share this post

Further Resources

You need further information on this topic?

Please do not hesitate to contact us with your individual question.

One of our project engineers will get back to you shortly.

Further Resources

You need further information on this topic?

Please do not hesitate to contact us with your individual question.

One of our project engineers will get back to you shortly.